Words by Nik De Padua and Chris Connolly

The threat is real!

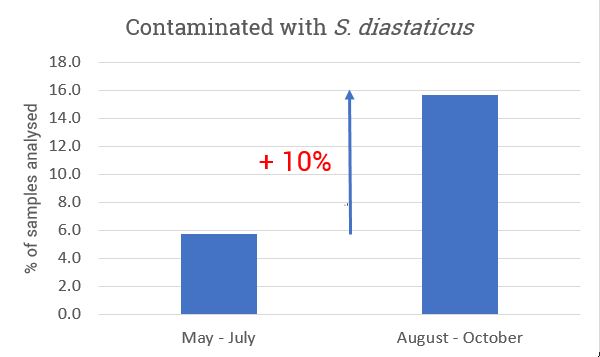

An increasing number of customers have reported exploding beer cans or noticeable off-flavours in their beers. Our micro-team did not waste much time and analysed the beers using our Pall’s GeneDisc Cycler, which is a real time PCR that performs rapid and sensitive detection of microorganisms. With this identifying the culprit easily and quickly – Saccharomyces cerevisiae var. diastaticus (or S. diastaticus for short)! Unfortunately this is an increasing trend we have noticed. Whilst only 5 beers received from May – July showed diastaticus contaminations, over 70 (!) samples have reached our lab from August – October being contaminated with diastaticus.

The problem is real!

What is S. Diastaticus?

Diastaticus is a variant of Saccharomyces cerevisiae that contains the STA1 gene. This STA1 gene is important to diastaticus ability to contaminate beer products, as it allows for the production of an enzyme called glucoamylase. Glucoamylase is an enzyme that can hydrolyse dextrins and starches in beer into fermentable sugars. This makes diastaticus a hyper-attenuator as it can ferment further than brewing yeast strains.

Why is Diastaticus considered a wild yeast spoiler?

Diastaticus is a major beer spoiler, due to the ability to produce glucoamylase. With dextrins and starches breaking down to smaller fermentable sugars, this will allow the yeast to continue fermenting, causing unwanted secondary fermentation. This will lead to not getting the desired beer you wanted.

Why is Diastaticus important?

Diastaticus presence in beer could lead to loss of body, off-flavours, turbidity, over-carbonation, gushing, alcohol level non-compliance. In worse scenarios leading to exploding cans/bottles and potential injuries to consumers. This makes diastaticus an important contaminant for brewers to be concerned about. In addition, a single cell could be enough to cause a can or bottle to explode even after months of being packaged. This poses serious economic and safety risk to brewers, as brewers will need to do product recalls. Also, in some cases leading to potential lawsuits.

How to detect Diastaticus?

Diastaticus can be introduced in numerous ways. This could be through dry hopping, in wort ingredients through the air, environmental air, personnel, and incoming yeast. One of the difficulties of detecting Diastaticus is that low levels can be hard to detect in the presence of other brewing yeast. No matter the level of diastaticus cells in finished beer, there is no acceptable level. Since diastaticus can be active at very low cell counts. The most common ways of detecting Diastaticus is through plating on selective media such as LCSM or starch plates, and through PCR with detection of STA genes. Under the microscope diastaticus yeast cell morphology are very similar to brewing yeast. The most reliable and safest method of detecting will be through the use of PCR targeting the STA1 gene, as PCR allows for increased sensitivity in testing, accurate identification of spoilage microorganisms and quicker turnaround time.

Preventing contamination

The main area to focus will be cleaning and sanitation. If cleaning procedures are not done the correct standard, formation of biofilms could happen. If diastaticus yeast have been active in the biofilm, this will make them more resistant to cleaning regimes. Cleaning control such as ATP swab testing and make sure best practice CIP is followed. Some critical control points are yeast slurries when propagating or re-pitching, incoming yeast, fermenters or bright tanks, packaged cans/bottles, the packaging environment and equipment. The yeast can live in both aerobic and anaerobic environments, in areas that have not been properly sanitized. Testing and cleaning of filling equipment is important, as it is a leading cause of contamination.

For further information on best cleaning practices, keep on reading: https://www.murphyandson.co.uk/cleaning-in-place-and-brewery-hygiene/