Enzymes – Long term thinking makes marginal gains add up

by Iain Kelly, Head of Technical, Murphy&Son

The end of the financial year often brings around a period of reflection and review of financial performance. It is a huge positive that so many companies (including Murphys) use this also as the time to begin collating, reporting and analysing environmental performance. In both these aspects, hitting the sum button of the spreadsheet column can often be revealing in terms of cumulative achievements from marginal gains.

It is often difficult in the high pressure environment of the brewhouse to make decisions beyond the immediate daily operations. Without the need of Capex investment, using tiny amounts of enzyme process aids can boost the profit and planet bottom lines.

Working with Brew Resourceful to independently collect and verify data at London Brewing Company, the annual benefits of a number of products was assessed and the financial and environmental benefits reported.

As a product that has been around for a number of years, the benefit of Trizyme is often underestimated with the enzyme often being used as a trouble shooter. However, this blend of α-amylase, β -glucanases and proteolytic enzyme can often offer a boost to extract and mashing efficiency.

Trizyme Data from London Brewing Company

| Without Trizyme | With Trizyme | Savings (£) | Savings CO2E (%) | |

| Brews p/a | 150 | 150 | 0 | |

| KG of Malt per brew | 202.5 | 194 | 9 | 4.30% |

| Cost of Malt P/A | £36,450.00 | £34,887.00 | £1,563.00 | |

| Cost of Trizyme PA | £624.00 | |||

| Net Costs | £36,450.00 | £35,511.00 | £939.00 | 3% |

| kgCO2e malt | 23389 | 22386 | 1003 | |

| kgCO2e Transport | 756 | 724 | 32 | |

| kg CO2e total | 24145 | 23110 | 1036 | 4.30% |

As shown in the data above, the use of Trizyme generated a 3% saving on malt bill. Combined with the cost of the enzyme itself, this offered the brewery a £939 saving on costs through the year – to offset the equivalent amount of CO2 would require the planting of 49 trees.

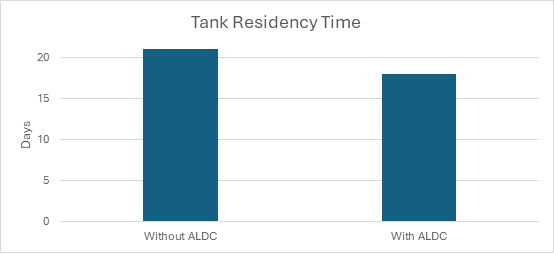

Murphys has been a supplier of ALDC (Alpha Acetolactate Decarboxylase) since the 1990’s and its use has been widespread reducing diacetyl and warding off dry- hop creep. On a savings front, the main boost of ALDC is the beneficial reduction in maturation time, reducing energy costs and freeing up tank capacity.

With the use of ALDC, the tank residency time was reduced by 15% with associated electricity costs reduced by 9%. Based on 75 fermentations per year, this offered the brewery a potential capacity increase of 17% which could amount to £91,606 worth of extra sales generated.

Completing the trio of enzymes, we also took a close look at Brewers Clarity. This selective endopeptidase targets proline rich proteins preventing the formation of hydrogen bonds with polyphenols. The net result of this is the streamlining of maturation and downstream processing increasing capacity and reducing tank residency time. In the closer examination of the performance of this product, tank residency per fermentation was reduced by half a day on a typical fermentation. The knock on gain for the brewer was a 2% increase in annual fermentation capacity with the opportunity to gain up to £11,000 in extra sales revenue.

Thanks to Brew Resourceful, we have proven how using additions as little as 3g per hl can really make a huge difference to the efficiency and profitability of a small brewery. In this instance alone potential sales revenue from added capacity was increased by over £100k with a 3% boost on raw material expenditure and real costs savings on fermentation refrigeration energy.

For more information on how we can help you benefit from enzymes and our other products please contact techsupport@murphyandson.co.uk