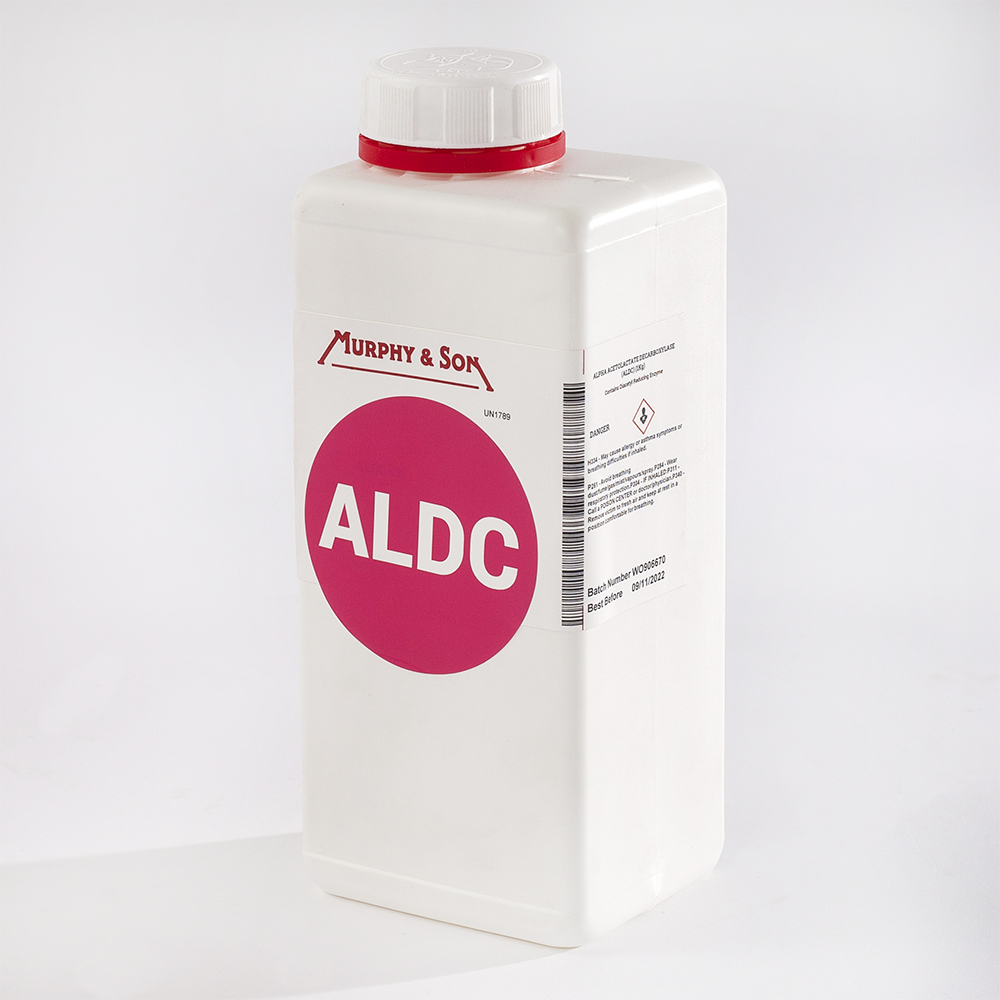

Alpha Acetolactate Decarboxylase (ALDC)

Bypass the formation of diacetyl by using ALDC. A simple addition makes it possible to consistently control a troublesome area of brewing and so, consistently prevent one of the most common flavour complaints. Diacetyl is expensive to measure and control, so by bypassing its formation altogether has become very popular with brewers, especially those brewing lagers and dry-hopped pale ales.

Kosher product.

-

Product description

ALDC (Alpha Acetolactate Decarboxylase) is an enzyme that reduces maturation times, increase efficiencies and increases production capacity. ALDC is produced from a submerged culture of Bacillus subtilis. ALDC causes the direct decarboxylation of alpha acetolactate to acetoin, thus avoids the production of Diacetyl.

Benefits

- Reduces Diacetyl production

- Significantly reduces maturation times

- More efficient vessel utilisation

- Improves beer quality

Application and Rates of Use

When used in the initial fermentation

The product can be mixed in with the cold wort at the beginning of fermentation at a rate of 1 to 5 grams per hectolitres of wort which equates to 10 to 50 ppm. To ensure even distribution of the enzyme, it is recommended that it be added as the wort is being run into the fermenter.

To find out more about how ALDC can help you with Hop Creep, please click here to view our blog ‘ALDC- for those about to hop’

Click here to read the ALDC sales sheet

-

Additional information

Additional information

Weight (kg) 1, 25

Stock Unit Pack

Stock-to-base Ratio 1

Available In Alpha Acetolactate Decarboxylase- (ALDC) (1kg), Alpha Acetolactate Decarboxylase- (ALDC) (5kg), Alpha Acetolactate Decarboxylase- (ALDC) (25kg)