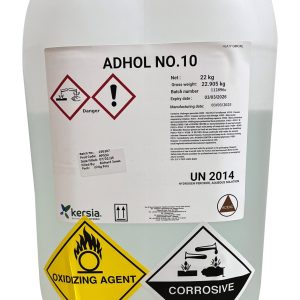

Nipac (30kg) (HZ)

Nipac can be used as an alternative to caustic based detergents in Breweries for the cleaning of Bright Beer Tanks and Tankers, whilst under CO₂ atmosphere.

This product falls within the Government Explosive Precursor and Poisions Legislation – to purchase we require the following information emailing to EPP@murphyandson.co.uk (if not, previously supplied):

- Name & personal address of person authorised to purchase on behalf of your company

- Photo ID – passport, driving license, trade or business ID

- Company VAT number

-

Product description

Nipac is excellent for mineral and protein removal and aids removal of beer and milk stains.It is safe for use on stainless steel and it is suitable for use in CIP applications.

In use concentrations of Nipac are application dependent and should be established during trials. Cleaning temperatures should be optimised during trials. However, it is not advisable to use Nitric Acid based products such as Nipac above 50°C. In contact with Copper or its alloys (Brass, etc), Nitric Acid based products will produce Toxic Gas.

CIP. For Clean in Place applications of Stainless Steel, glass and synthetic resin lined vessels or pipelines; Nipac is typically circulated at 1% to 4% v/v. It is advisable to check compatibility before using Nipac with synthetic resins. Nipac can be used in a CO2 atmosphere without degradation. Before circulating the detergent, pre-rinsing with water is advisable.

-

Additional information

Additional information

Weight (kg) 30

Stock Unit Each

Stock-to-base Ratio 1

Available In Nipac B (30kg)