The key to brewing a successful NALAB is to gain a high level of control over the entire process. The ability to accurately measure brewing outcomes is, therefore, paramount. HPLC, an advanced analytical technique, provides the brewer the ability to analyse the sugar composition in either the wort or in the finished beer. This level of analysis provides an insight into the effectiveness of their NALAB production methods, allowing them to adjust accordingly to optimise the process.

What is a NALAB?

According to EU Regulation 1169/2011 beers with an abv greater than 1.2% are listed as alcoholic. In the UK the limit for no-alcohol/alcohol free beer is 0.05 % abv, while low alcohol is defined as being between 0.05 – 1.2 %. In most European countries, however, the limit for no-alcohol is 0.5 %.

Due to the lower limit within the UK, the majority of NALABs produced are defined as low rather than non-alcoholic. To reduce the abv to below 0.05 % and achieve the non-alcoholic status dealcoholisation methods have to be employed. These methods require highly specialised equipment and, consequently, involve significant capital investment. As such, true non-alcoholic beer in the UK is generally limited to the larger breweries, and most typically to the lager producers.

For breweries without dealcoholisation equipment other methods can be employed to produce low-alcohol beers.

Mashing Methods for NALAB Production

One method for the production of NALABs is to make a poorly fermentable wort. To do this the brewer needs to prevent β-amylase from working in the mash. β-amylase is the enzyme responsible for breaking up starch molecules into singular maltose units, causing maltose to be the most prominent sugar in the mash.

| Sugar | Percentage of extract weight |

| Maltose | 45-60 |

| Maltotriose | 10-20 |

| Glucose | 10-15 |

| Fructose | 2-5 |

| Sucrose | 2-5 |

| Dextrins | 10-25 |

| Fermentable Material | 70-75 |

The optimum temperature for β-amylase activity is 63-65°C and above 70°C the enzyme is denatured. Typically brewers will use a mash temperature of 75°C and up to 82°C, to rapidly denature β-amylase and to greatly reduce the activity of α-amylase. At higher temperatures there is an increased risk of extracting undesirable compounds from the malt. Furthermore, non-enzymatic starch hydrolysis increases with temperature, higher temperatures will lead to unacceptable concentrations of fermentable sugars.

The use of maltose negative yeast strains can also be employed to produce low ABV beers. In this case, the production of glucose should be minimised. The main enzyme responsible for the breaking down starch into glucose in the mash is α-glucosidase, which has an optimal temperature range of 40-44°C and is denatured at 70°C. Typically, a single mash stand at 75°C is likely to provide the lowest abv possible.

The use of high mashing temperatures along with a maltose negative yeast strain further down the line is a sure way of limiting the abv of the final product.

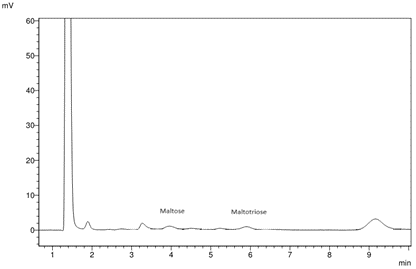

Below are two examples of low-alcohol beers analysed with HPLC at Murphy and Son.

NALAB 1 used a mashing temperature above 75°C in an effort to limit glucose and maltose production. Fermentation was conducted with a maltose negative yeast. HPLC analysis revealed maltose (17.1 g/L) and maltotriose (6.3 g/L) concentrations far higher than the target, and helped explained the sweetness attributed to this beer. Furthermore, high levels of sugars remaining in beer post packaging pose a greater risk of microbiological spoilage than beers with low levels of sugar. The brewer is now able to adjust their mashing regime and assess the effect using HPLC.

NALAB 2 was brewed with a higher mash temperature of 82°C to limit the fermentability. The HPLC analysis shows little residual sugar indicating that the mashing regime has been successful in reducing maltose (0.6 g/L) and maltotriose (0.3 g/L) formation.