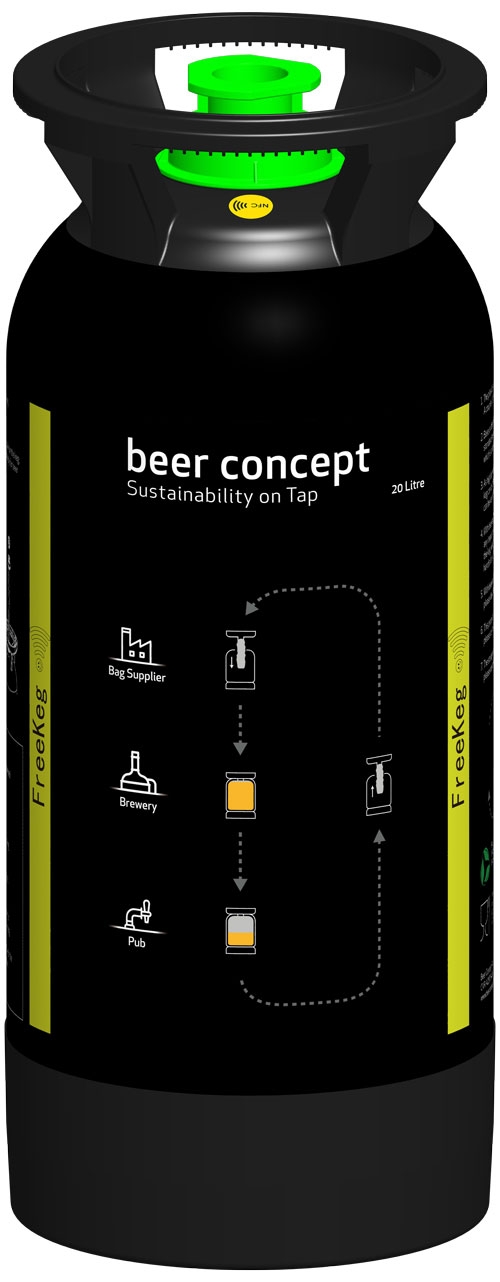

FreeKeg

Meet ‘FreeKeg’, where functionality, quality, and price come together to meet market demands. FreeKeg offers economic benefits for both export and local recycling markets.

The Freekeg is fitted with a replaceable FreeKeg Liner, available with a S or K coupler.

-

Product description

BENEFITS

- 75% reduction in plastic waste compared with single-use kegs in the market.

- FreeKeg is designed for maximum safety under pressure.

- The built-in overpressure valve on the liquid slide eliminates the risk of explosions.

- Inclusion of fiberglass composite material which is strong, flexible and in rare cases of failure, pressure is gradually released through small cracks.

- The valve activates even when the keg is 100% filled with liquid.

- Features a sturdy keg neck and threading that ensure optimal functionality.

Economy:

- 10% lower price compared to single-use plastic kegs.

- Competitive prices linked to the PET Keg Index.

- Exports still achieve a 10% savings in the first lifecycle.

✅ Step-by-Step Guide: Filling a FreeKeg (overview)

This guide shows how to fill a FreeKeg using its replaceable inner bag and compressed air. Follow each step carefully to ensure safe and proper filling.

🧰 What You’ll Need:

- A FreeKeg shell with a fresh inner bag installed

- Filling coupler (correct type for your keg: S or K-type)

- Compressed air supply with pressure gauge

- Product source (e.g., beverage tank)

- Air vent access

- Optional: bag installation tool (for bag replacement)

🛠 Before You Start: Set Up and Safety

- Visual inspection: Make sure the keg and overpressure valve are not damaged or blocked.

- Install new bag (if not already done):

-

- First, neutralize pressure (see Step 2).

- Use a tool to remove the used bag and insert a new one by tightening clockwise.

- Check max pressures:

-

- Filling pressure should not exceed 1.5 bar.

- Never exceed 3.5 bar for dispensing.

- Safety valve opens automatically at 8 bar.

🔄 Step 1: Neutralise Pressure (If Replacing the Bag)

- Use a coupler without hoses.

- Attach it to the keg’s head.

- Press the handle down to release the pressure (you’ll hear a hissing sound).

- Wait 5 minutes to ensure full depressurisation.

💨 Step 2: Add Counterpressure (Compressed Air)

- Connect your compressed air source (via air gun with gauge) to the CO₂ outlet on the coupler.

- Attach and engage the coupler.

- Fill the keg with air until pressure reaches 1.5 bar.

This stabilizes pressure around the bag, helping avoid foaming during filling.

🍺 Step 3: Fill the Keg with Beverage

- Connect the filling coupler to your tank.

- Attach the coupler to the FreeKeg and open the liquid valve fully.

- Wait ~20 seconds to allow flow to begin.

- Slowly open the air vent to 50% on the coupler and leave for 2–5 minutes.

- Then open the air vent on the coupler to 100% and continue filling.

✅ Stop filling when:

- The keg is full, or

- The desired weight or volume is reached.

- Close the liquid valve.

You may need to add top pressure to the tank containing the beverage to force it into the kegs as the level drops or use a pump.

🧪 Step 4: Check for Functionality

After filling, check:

- That the keg holds pressure at 1.5 bar for at least 24 hours (recommended test).

- For leaks or damage around the valve or bag.

- That the coupler is sealed properly.

🧼 Additional Notes:

- Always use a fresh bag—never reuse.

- Store filled kegs below 35°C and upright.

- Do not shake or roll the keg, especially when filled with carbonated products.

-

Additional information

Additional information

Weight (L) 20 K I 20 S I 30 K I 30 S

Stock Unit Each

Stock-to-base-ratio 1

Available In FreeKeg (20L K), FreeKeg (30L K), FreeKeg (20L S), FreeKeg (30L S)