Written in collaboration with Víctor Villouta Poblete

Beer contains about 90-95% water, and the importance of the liquor to final beer quality shouldn’t be under-estimated. Correct water adjustments can make the difference between a good and an excellent beer (style). Now is the time to wake up to this primary ingredient and start to spend time, effort and a little expense to develop a true understanding and equip yourself with best practice guidelines and equipment to perfect your beverage and grow your business.

What is CapDi?

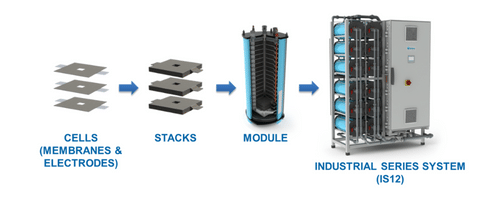

CapDI is a tunable water deionization technology that is designed to remove dissolved salts from a variety of water sources ranging from tap water and brackish groundwater to industrial process water. The systems are composed of modules, which are built from stacks comprising of membrane and electrode cells (Figure 1)

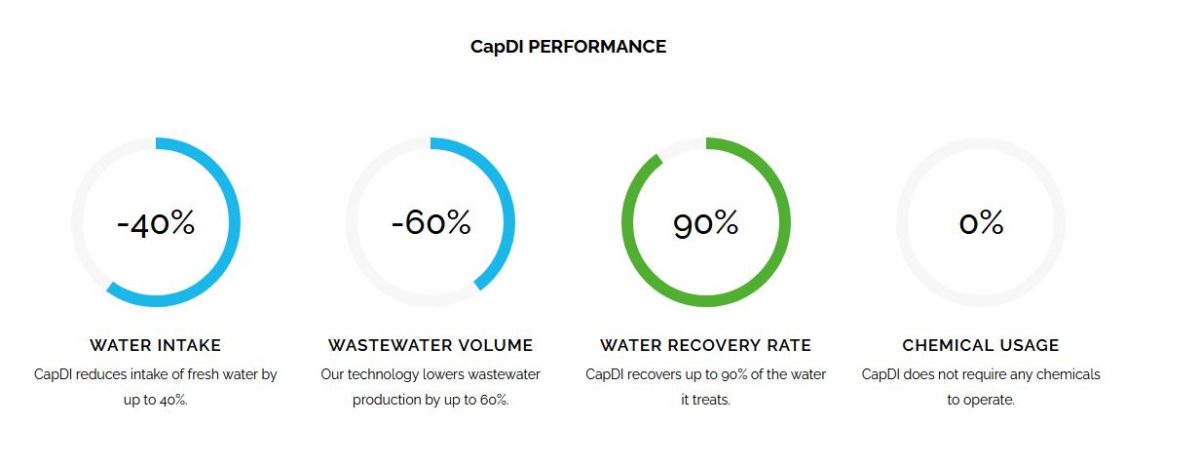

Water contains different levels of Total Suspended Solids (TSS), disinfectants (chlorine, chloramine), and -depending on the region – high or low levels of minerals as dissolved solids (TDS). While water treatment systems, such as Reverse osmosis or ion exchange filters, are already used in the beverage industry, not all of them are cost effective, can cause high water wastage, create very generic water and suffer from high maintenance costs. The beverage industry was ready for a fresh, innovative alternative!

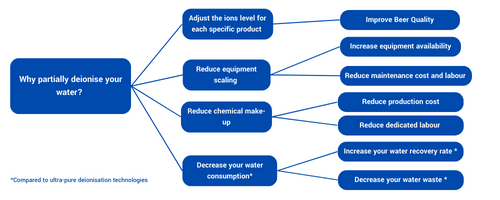

Why you should partially deionise your water.

Control your water with Membrane Capacitive Deionisation (CapDi) to achieve best results for all your beverage needs. CapDI uses digital controls to instantly adjust and maintain the water quality with laser sighted accuracy and is able to not only achieve but to maintain your exact water quality standards providing consistent taste and TDS reduction throughout your entire operation.

Capdi offers

- Consistent & better quality water, taste and mineral content

- Tunability –adjustable TDS reduction between 25 – 90% depending on customer needs, eliminating the requirement for blending to achieve a specific water quality.

- Low environmental impact

- Low operational and maintenance requirements; low maintenance costs

- Simplified pretreatment

- Automated cleaning

- High degree of automation, feedback and monitoring

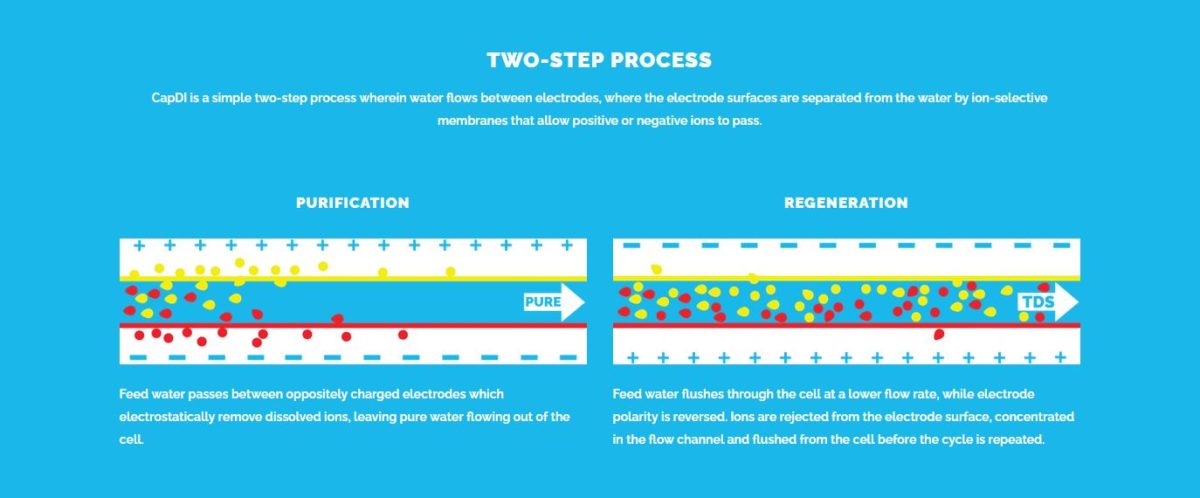

How does CapDi work?

CapDI is a simple two-step process wherein water flows between electrodes, allowing adjustable TDS reduction between 25 – 90% depending on customer needs, eliminating the requirement for blending to achieve a specific water quality. The customer sets their desired reduction rate and CapDI maintains this level, continually adjusting itself to account for any fluctuations in feed water characteristics

- Purification

Feed water passes between oppositely charged electrodes which remove and store dissolved ions, leaving low TDS (total dissolved solids) water

2. Regeneration

Reversal of electrode polarity rejects stored ions regenerating the system Ions are flushed from the system with a low flow

You can can browse the full range of Voltea CapDi products here.